LEICA AKADEMIE WORKSHOPS

The photography book remains the foremost delivery system of a photographer’s vision.

In the book the sum equals more than the parts. In the world of photography all the leading practitioners have made their work and their names known by way of a major publication. For many serious photographers, however, the book is a goal difficult to realize. Often the technical steps in making a book remain a mystery

Ralph (Gibson) strongly believes that these are the golden years of the photography book. This workshop is designed to help you explore the process with guidance from a true master of the craft.

From e-brochure for BookMaking Workshop- Ralph Gibson

Book making, specifically photo books, has long been an interest. My first foray in this format was in 1976 for an undergraduate photography course. RC coated paper glued together, plastic comb bound and with vinyl; covers, it survives minus the binding and with the prints peeling apart.

Over the years, prints have gone into shoe-sized boxes (4x6’s printed by drug stores), printing paper boxes (during my chemical darkroom days), and various types of binders using plastic sleeves. This is how most folks GenX and older seem to go about it. The digital age made all that stuff disappear into phones and hard drives. This is a preamble to how all these methods pale in comparison to a physical print let alone a photo book. Over the years, I’ve built up a small collection of photography books (don’t have any Ralph Gibson ones) and thought about how cool it could be to put one together.

Well, up until a few years ago, a case bound, custom printed book was not an option for most of us.

Then came Apple, Shutterfly etc with different quality and price levels but with an unappealing price to quality ratio. Adding to make that not a viable option for me is that I just like making my own prints. As for digital print technology, while it became acceptable around 2006, it still left something to be desired. Epson came out with the P800 in 2015. With that generation of printers, together with Imageprint, a RIP (raster imaging processing) software that runs the printer, digital color printing surpassed analog and can compete with B&W chemical printing. Rolls of double sided paper make printing long sheets which can be folded and organized into signatures, if not easy, certainly doable. Since then, I’ve been sufficiently happy with the quality of digital printing to ideate more and more about printing the content for a photo book. So nothing to it but to do it, right?

Well, first like any boomer gen college graduate, I read up on it- bought some books.For all of the ills brought about the digital age, YouTube videos can be way helpful once one sifts through all the content of widely varying quality out there.

The Incidental Bookbinder

Bookbinding newbies are generally advised to use blank copy paper to make the signatures that form the book’s content, then make the book. Going through all that to wind up with a blank book was not my idea of a good time. As alluded to in the preamble, the motivation is more in the content of the book, then as an exercise in printing, sequencing, layout, double page spreads rather than the book as an object of art and craft in itself. Choosing last year’s summer vacation photos as the content gave me the opportunity to exercise all the above while still not being so important that the inevitable mistakes would result in a total loss. Thing is, we took a lot of photos. To place in perspective, Mr Gibson’s 3 day workshop leads to a 16 page signature book dummy which then gets printed and bound by Gibson’s company. I wound up with 18 signatures which were separated into 2 volumes. Plenty of practice material for folding and sewing. Culling through the files, doing the post processing from RAW to TIFF of the proper file size and sequencing them chronologically to tell a story was a time consuming task necessary for but only preliminary to making a book.

Once I had a chronologic sequence and TIFF’s with the desired resolution, the next step was sequencing them in sheets such that 4 sheets can be made into a 16 page signature. Being a complete novice, I could not keep the sequencing in my head. Workflow was to print a collage of 3x5’s on an A2 sheet, cut into individual photos, tape onto letter sized paper, number 1-16.

A mini loose leaf 16 page picture book dummy (pun there?) was used as a guide for printing the sheets.

Even, then there were some printed in reverse sequence or upside down. Only a few and those were used to make the 3x5’s.

Bookbinding as a Woodworking Activity

As an English chap put it, most of my hobbies have a gearhead component. Fueling my enthusiasm for bookbinding was- I get to make jigs. My intro to woodworking (as opposed to carpentry) came through picture frames Bookmaking in turn provided an opportunity to generate “bespoke equipment”. Making the jigs allowed me to move the process forward while staying in my comfort zone and procrastinating a bit re actually making a book.

While engaging in new endeavors, unanticipated complications invariably pop up. The topic of grain direction came up very quickly in reading up on making signatures. The inkpress rolls purchased for making the printed pages are economical and of good if not great quality; not as good as baryta or the best matte paper, but less easily damaged than matte surfaces and baryta does not come double-sided. Grain direction is not specified. It has a pronounced curl to it which overrides whatever grain direction it has, Given the luster coating on both sides I’m hoping it’s pretty dimensionally stable. We’ll find out in 15 years or so. An immediate problem was keeping it from curling as least while going through the printer. Thus the following jigs- the cylinder to begin reversing the curl,

and the rectangular press to keep it under pressure- were made as putting a bunch of books on top of the pages was annoying my organized and tidy spouse.

The smaller book press was put to use to help keep the signatures flat while awaiting the next step.

The book presses were a challenging but rewarding process. The all metal metal ones available at Talas and on eBay are pretty but expensive and the wooden ones unappealing. The design was guided by remnant countertop piece found at CrossCut lumber in Portland and the white maple was made of leftovers from prior project. The screws were ordered from McMasterCarr. The rest came from the Home Depot pipe section with 8 pieces of pipe fittings requiring alteration by my friendly local machinist.

Finally, Making a Book

Folding 70 some sheets of double coated inkjet printing paper consistently was facilitated by a scoring jig.

I started off with teflon folders which did not work to my satisfaction, Switching over to bone folders produced better results

A sewing punching cradle helped this newbie keep the guide holes square and uniform.

The sewing stand was the first jig I made for bookbinding.

Thus the metal posts. I did not feel like springing for a wood tap and die jig along with the learning curve required.

Said tap and die threader kit did wind up being purchased for the backing board jig as the screws seemed necessary to hold the case at the desired position for gluing then rounding the back.

I had been advised to avoid rounding the back as it is a difficult procedure, but I went ahead with it. Learning points: I waited too long for the glue to set before molding and as a result needing more force to mold to a sorta mushroom shape. This in turn resulted in the 1 inch wood screws not being able to keep the block in place.

I had anticipated that might happen as the backing boards have a lip to be able to sit in a Moxon vise, This resulted in a workspace change from my office/digital printing area to my workshop.

This was just as well, as the remaining steps involved generating leather and paper waste inside the house, which would have not endeared me to DW.

My workshop Moxon vise had been previously tested on a catalog to confirm that it could work for ploughing the case.

The setup worked well in the actual ploughing of the case, although the chisel needed to be sharpened once as the coating of the paper seemed to dull the chisel.

Before ploughing:

And partway through:

For all the attractiveness of leather bound books, I don’t think we have a single one in our home up to now. It stands then, if I’m going to go through all this trouble, my first book might as well have a leather cover. Ideation progressed to plan when my sister and brother in law, who have a leather goods business, asked us to pick up some hides in Napa while staying overnight in St Helena en route to visit LA.. The prices were more reasonable than the bookbinding supply stores and there was the added benefit of in person inspection. When talking about the project with Soo and Roddy, they kindly let us have a number or hides for practice; many of them large enough to use for future covers. It took a few hours of practice to get sufficiently comfortable with the tools and material to prepare my first cover. Much to my relief, the paring was adequate. I had also done a practice glue up which went well thanks to advice from the owner of The Accidental Bookbinder. It’s noteworthy and fortunate that the only retail bookbinding store on the West Coast is only 40 miles away. Patricia was very patient and informative, and her recommendation to use Nori paste for the leather which she had in stock along with a few other things I needed was worth the trip.

While the case ploughing and leather paring had gone well, when laying the book out in I found that the non-pared width extender 3/16th’s past the lateral edge of the cover boards. Lesson: I had painstakingly done the counter-sinking and slots for the binding ribbons. But I did not maintain the 1/4th inch gap between the spine and the cover boards the instructions called for.

This resulted in one of the inside end pages bunching up where the body meets the inside cover. No photo, but take my word- it looked ugly. I sliced off the offending area and matched it with leftover paper.

Once that was done, I needed to repair an even worse defect- one of the covers was uneven with no overhand over the block!

I needed to re-plough the lateral side of the block to even it up and have the covers symmetrical

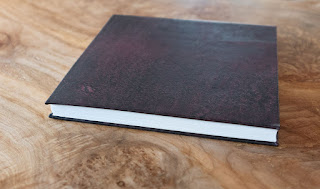

A little repair work and much to my relief, I had a book of acceptable quality for its function.

It still needs a title on the spine for ready identification, as I’m hoping it will be the first of many. I’m exploring options. Lettering and tooling covers is a whole story I haven’t even started on. What I’ve done so far has made me a firm convert to Bookbinding as a fulfilling activity in and of itself. DW and her sister are already talking of making books themselves.

Our twentieth wedding anniversary was last year. We still don’t have a wedding album. That is one intermediate range goal once I feel sufficiently competent to do it right.